Industrial Maintenance: Keeping Your Machinery in Top Shape

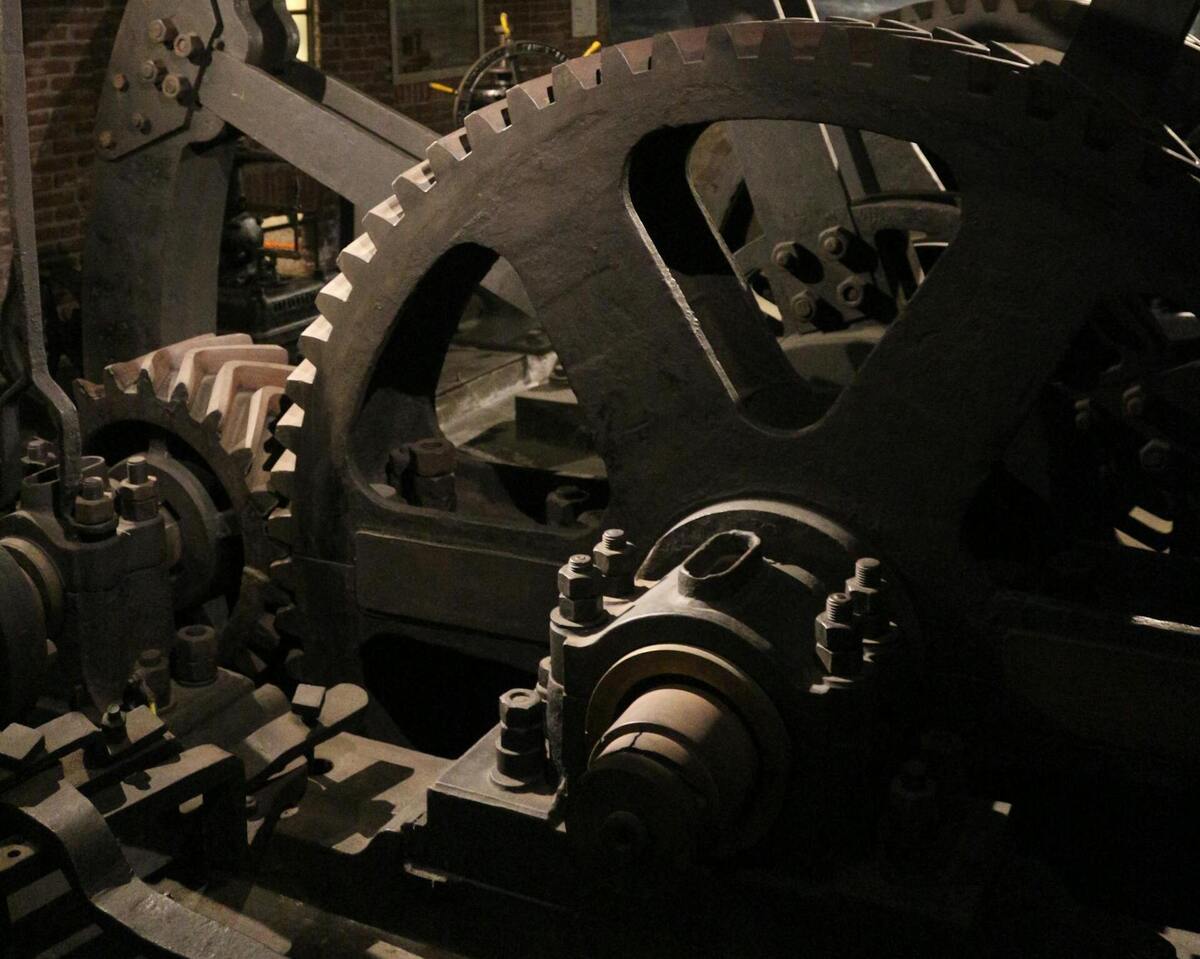

In the bustling world of industry, machinery plays a pivotal role in ensuring smooth operations. Regular industrial maintenance is essential in preventing costly breakdowns and maximizing the lifespan of equipment. It’s also important to rely on trusted component suppliers which offers high-quality chains and sprockets tailored for industrial use. By adhering to maintenance best practices and choosing the right parts, businesses can reduce downtime and enhance safety and efficiency on the shop floor.

Industrial Maintenance: What You Need To Know

Industrial maintenance encompasses a wide range of activities focused on the upkeep of machinery and equipment used across multiple sectors. This includes everything from regular servicing and inspections to emergency repairs when equipment malfunctions. The primary aim is to prevent unexpected equipment failures that can disrupt productivity and incur hefty expenses.

A key part of effective maintenance involves using reliable, durable components. For example, choosing quality chains and sprocket can help ensure machinery continues to run smoothly and safely. Proper components reduce wear, extend machinery life, and support long-term performance under heavy industrial workloads.

Why is Industrial Maintenance Essential?

One of the main reasons to prioritize maintenance is to avoid production delays. These delays can stem from minor issues that, if left unattended, escalate into significant faults. In a competitive market, every minute counts; a breakdown can quickly lead to lost revenue. Furthermore, routine maintenance can reduce operational costs through improved energy efficiency and lower repair expenses.

Another crucial factor is worker safety. Malfunctioning equipment poses dangers to the machinery itself and to the personnel operating it. Keeping machinery in optimal condition minimizes risks and ensures a safe working environment. Additionally, it helps in protecting the integrity of the inventory, reducing the chances of damaged products resulting from equipment failure.

Best Practices for Industrial Machinery Maintenance

To keep machinery in prime condition, it is essential to adopt an organized maintenance strategy. Here are some best practices that every business should consider.

Regular Inspections and Monitoring

Daily inspections are fundamental in identifying potential wear and damage. Monitoring machinery components allows operators to spot signs of wear before they escalate into costly repairs. Regular checks for vibration, temperature, and friction are vital during these inspections, as these indicators can reveal underlying issues that may not be immediately apparent.

Incorporating a checklist can help streamline this process, ensuring that all aspects of the equipment are examined. This systematic approach allows for budgeting and replacing components ahead of time, further minimizing downtime and operational disruption.

Keeping Machinery Clean

A clean machine is a reliable machine. Contaminated equipment can lead to severe operational challenges, including costly breakdowns. It’s crucial to maintain a proper working environment, especially for machines that operate in hazardous areas. Regularly servicing filters and seals prevents contamination that can impact machinery performance.

Additionally, always ensure that the cab remains clean to prevent a vacuum build-up, which could affect operation. From excavators to rollers, cleanliness is key in maintaining optimal function and longevity.

Scheduled Maintenance Plan

Establishing a maintenance schedule is critical for keeping machinery at peak performance. Regularly checking and replacing essential components, such as lubricants, belt adjustments, and oils, should be performed by a knowledgeable technician who is familiar with the specific machinery.

Having a structured maintenance plan can lead to fewer routine breakdowns and ensure that the machinery is consistently operating at its best. This not only helps maintain efficiency but also grows the return on investment (ROI) for the business.

Using Quality Lubricants

Lubrication is one of the most vital maintenance checks for machinery. Quality lubricants reduce friction, thereby extending the lifespan and functionality of equipment. Regularly testing lubricants helps technicians diagnose specific issues within the machinery by analyzing particles in the used oil.

Selecting the correct lubricants tailored for each type of equipment is crucial. New operators should always refer to the manufacturer’s recommendations to ensure compatibility with their machinery. A well-lubricated machine runs more smoothly and is less likely to encounter operational issues.

Protection During Storage

Proper storage is essential to maintain machinery when not in use. Keeping equipment stored in a sheltered location protects it from environmental damage caused by factors like weather and contamination. Ideal storage locations should feature controlled humidity and temperature, reducing the risk of rust and rot.

Moreover, periodically running stored machinery ensures that it remains operational and effective. Regular oil-mist lubrication also helps safeguard against deterioration while not in use.

Record-Keeping for Maintenance

Documenting maintenance activities is vital for seamless operations. Keeping track of inspection schedules and service history prevents errors and identifies recurring issues. This meticulous record-keeping can pinpoint when specific components require more attention.

Hands-On Knowledge of Equipment

A thorough understanding of machinery manuals empowers operators to appreciate the equipment’s capabilities and limitations. Knowledge is power when it comes to maintaining machinery efficiently. Familiarizing oneself with the components, as well as following the manufacturer’s guidelines, is essential in mitigating accidents and damages.

By adhering to a structured maintenance plan, understanding the machinery thoroughly, and employing best practices, industrial operators can ensure their equipment remains in exceptional condition. This not only safeguards against unexpected failures but also creates a more efficient and productive operational environment.

In sum, an effective industrial maintenance strategy is key to enhancing machinery functionality, safety, and longevity. Companies that take maintenance seriously are better equipped to reduce downtime and extend the useful life of their equipment. Whether you’re scheduling routine checks or replacing worn-out components, it’s vital to use dependable parts from trusted sources. For durable, high-performance chains and sprockets, AGM Canada offers a reliable solution tailored to industrial needs. Don’t wait for machinery failures to disrupt your business, take proactive steps today.